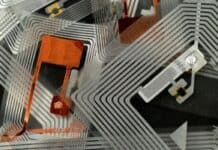

Tag: rfid technology

RFID Technology and Its Use in Asset Protection

RFID technology allows companies to know where in their process any particular asset is, so they can monitor the speed of production, the time of delivery, or any other factor that will help them to see how long their processes actually take—and control assets by knowing where they are at any point in time.

10 RFID Case Study Companies and Lessons Learned

GS1 and the ECR Community Shrinkage and On-Shelf Availability Group commissioned a research study to look at 10 RFID case study companies.

Why Point-of-Sale Activation Technology Has Been Heralded as a Kingmaker

In a world where opposites attract, denial of service could be a force for good and put to commercial use, particularly in retail where organized retail crime gangs and opportunist thieves have had a free hand at disrupting legitimate business.

Checkpoint Announces Deployment of Large-Scale RFID Program with Polish Fashion Retail Group

Checkpoint Systems recently announced at NRF 2019 that it is expanding its relationship with Polish fashion retail group LPP with the deployment of a...

LPF Announces Nedap as Newest Doctorate-Level Partner

Nedap, a global leader in RFID retail solutions, will share their expertise by contributing to the new RFID content for the LPC and LPQ certification courses.

5 Ways Employees Are Stealing from Your Stores Right Now

Implementing targeted theft-deterrent strategies depends on consistent record-keeping, organization, and pattern recognition. A data-driven incident management process is the only way to keep pace with an extremely adaptable foe.

The Reinvention of Retail Stock Management

Between the physical and online space, ever-diminishing timelines, and the possibilities of pinpointing stock on its return journey (the so-called reverse logistics model), you have all the ingredients for a parallel universe where nothing is quite what it seems.

RFID Blocking Wallets: Are They Necessary?

Now that people are aware that information on their cards, and even their passports, can be read wirelessly and remotely, many are looking for ways to protect themselves. Purchasing an RFID blocking wallet (or sleeve, or pouch) is one way. Isn't it?

RFID White Paper (Nedap)

Today's shoppers expect the entire shopping experience to be fun. They want to be inspired, find what they want and the size they need,...

6 Steps to Calculate ROI for New RFID Solutions

With appropriate RFID solutions, store associates can easily restock merchandise on the sales floor, replenish out-of-stock items, improve inventory accuracy at the point of...