Over the past few years, it has been hard to pick up a newspaper or magazine without seeing an article about RFID. Publications such as USA Today, Fortune, BusinessWeek, PC Magazine, CFO, and, of course, Loss Prevention are just a few of the publications that have featured articles about various aspects of RFID.

This article will provide an update on the current status of RFID in the marketplace and will help the loss prevention professional determine how to prepare for utilization of this technology.

What is RFID?

RFID stands for Radio Frequency Identification and, this may surprise you, RFID is not new. In fact, it has been around since World War II and has been used in a wide variety of settings and applications. However, only recent developments have made RFID a practical means of changing the way retailers do business.

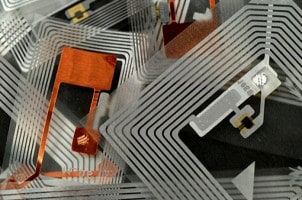

Basically, RFID consists of a RF reader and a tag that contains a microchip and an antenna. The RF reader sends out an RF signal and listens for any tags within range to respond. One of RFID’s biggest advantages is that it is a non-line-of-sight solution. As a comparison, in today’s bar code environment, a scanner must actually be able to “see” the barcode on an item in order to read it. With RFID, this is not required. This means a tag can be read through product packaging, inside a shopping cart or shopping bag, or even through clothing.

However, the “read field” of the RF reader is not unlimited and is tied to the size of the tag and the amount of power available to it. One of the great advances in RFID technology was the development of “passive” tags. This means no battery or source of power is required on the tag itself. Instead, the tag uses power collected from the signal transmitted from the RF reader. However, because of the size of tags desirable in the retail setting and their lack of an independent power source, the read field is limited to a relatively small area—perhaps ten feet or less in most applications.

In the past few years, RFID has gained prominence and is being looked to for manydifferent applications. There are five primary reasons for this new surge in interest.

1. The decreasing size of microchips and electronic components that allows a tag that is unobtrusive…as small as a grain of sand.

2. Development of global standards and protocols, such as EPC (electronic product code) and ISO. This is evidenced by the fact that the Auto-ID Center, an RFID think tank, is owned by the UCC (Uniform Code Council) and EAN International.

3. The shrinking costs of both readers and tags, which makes utilization of the technology more likely to generate a convincing return on investment to the business community.

4. The implementation of IT infrastructures, equipment, and internet capabilities that supports the adoption of RFID and allows for data generated to be stored, reported, and analyzed.

5. End-user demand and mandates from mega-organizations such as Wal-Mart and the U.S. Department of Defense (DoD) that will require suppliers to tag their products with RFID tags.

Where and How Is RFID Being Used Today?

While those of us in the retail industry tend to think of RFID as a retail tool, RFID is already being used in a wide variety of industries and in many different applications. Following are a few examples.

Automated Payment Systems. Perhaps the most recognizable use of RFID for payment comes in the E-Z Pass system that automates the collection of tolls and allows drivers to speed through automated toll booths at speeds of up to 45 miles per hour. Others might recognize the Speed pass system that allows a consumer to wave a key fob in front of a gas pump and have the cost charged automatically. This could be a blueprint for a more seamless self-check outin the retail store.

Asset Tracking. In one of the most significant mandates boosting the adoption of RFID, the U.S. Department of Defense (DoD) mandated the use of RFID by their 37,000 suppliers starting in January 2005 with full compliance in all facilities scheduled by 2010. One upscale hotel chain is using RFID to tag flat-screen TVs to ensure they don’t become aliability.

Distribution and Logistics. Some experts estimate there could be anywhere from a 5 to 35 percent reduction in labor costs by implementing RFID, plus the potential for greater accuracy. NYK Logistics in Long Beach, CA implemented RFID to automate more than 90 percent of their yard operations and has increased efficiency, reduced errors, and increased overall through put of their operations.

Airline Baggage Handling. McCarran International Airport in Las Vegas, NV, and Jacksonville (FL) International Airport are two of the prominent airports currently implementing RFID for baggage tracking. McCarran has begun a $125 million project to use RFID in its baggage handling system. Officials there anticipate a reduction in mishandled bags of 15 to 30 percent.

Access Control and Visitor Management. With the ability of RFID to store multiple data bits and cross-reference them to other databases via the reader, it is a logical choice for access control and visitor management allowing more levels of discrete control and user-friendliness.

Pharmaceuticals. The US Food and Drug Administration (FDA) is bolstering regulations regarding the manufacture and import of counterfeit drugs, including technology recommendations that include RFID technology as part of the solution. In addition to the anti-counterfeiting benefits of an “electronic pedigree,” RFID could play a role in drug recalls and patient safety.

Managing Evacuations. One provider of RFID-enabled systems recently introduced an emergency evacuation system designed to ensure that all employees have left the facility and are accounted for at a designated “muster point.”

Hot Dogs and Nachos. In one of the more unique applications, the NFL Seattle Seahawks have used RFID to automate their food concessions at their home stadium. Perhaps it is not so surprising given the owner of the team, Paul Allen, is one of the co-founders of Microsoft.

Tracking Pets and Guitars. Veterinarians are injecting a microchip under the skin of dogs and cats to enable a reader wand to be waved over the pet to identify its owner. Snagg, a California company, specializes in RFID tags for guitars and amps to reduce thefts of high-priced instruments and counterfeit products.The applications for RFID seem boundless. And, of course, there is the retail market…

RFID and the Retail Industry

Why does the retail segment have such appeal and allure to product manufacturers, RFID providers, consumers, and retailers? It comes down to one issue—volume.

With thousands of locations, millions of products, and high inventory turn rates, the retail marketplace is the primary future for RFID benefits. RFID suppliers obviously see great potential revenue given the high number of locations and products. Manufacturers see the opportunity to reduce loss rates from counterfeits and forgeries and product diversions that ultimately affect their margins. Retailers see the opportunity to reduce costs, improve sales, and increase customer satisfaction primarily through streamlined inventory controls.

RFID suppliers such as IBM, Phillips, Texas Instruments, ADT Tyco, Checkpoint Systems, and many others are all actively involved in RFID. Manufacturers such as Gillette, Proctor & Gamble, Nestle, Johnson & Johnson, and others are seeing the potential benefits. And, most importantly, retailers are clearly driving the adoption of RFID.

Most of the attention has been focused on Wal-Mart, for obvious reasons. Wal-Mart has been among the most aggressive in pushing RFID. They have already tested RFID in select distribution centers with top suppliers and have called these tests a success. “To date, no glitches – only positive glimpses of what’s to come,” says Linda Dillman, executive vice president and CIO for Wal-Mart Stores.

Wal-Mart has mandated their top suppliers tag to the pallet and case level with RFID by January 2005 with smaller suppliers on board by the end of 2006. But, Wal-Mart is not alone. Consider the following sample of retailers pushing for RFID:

Metro AG—One of the most visible retailers in promoting RFID and the fifth-largest retailer in the world, this German-based conglomerate rolled out their “Store of the Future” this past January at the National Retail Federation show in New York based on RFID. They have also mandated RFID at the pallet level for their top 100 vendors by November 2004, an earlier deadline than Wal-Mart’s.

Target—The fourth largest retailer in the U.S. has mandated RFID tags on pallets and cases from its top suppliers by late Spring 2005 for select distribution facilities and plans to extend the mandate to all shipments by spring of 2007.

Albertsons—The second largest food and drug retailer in the U.S. plans to require suppliers to tag pallets and cases by April 2005.

Best Buy—This U.S. electronics retailers has mandated top suppliers to apply RFID tags to cases and pallets by January 2006 with all suppliers being on-board by May 2007.

And, the list could soon expand to include U.K. retailers likeTesco, a grocery chain, and Marks and Spencer, the department store chain. In the U.S., other retailers who are looking at RFID include CVS/pharmacy, Limited Brands, and Home Depot.

What Are the Benefits for Implementing RFID?

First, one must recognize a simple truth—RFID is not a loss prevention technology or system. In fact, senior executives usually list shrink or shortage reductions significantly behind other benefits in terms of importance to the organization.

“This is a technology that’s going to provide an infrastructure for doing a lot of things,” says Pete Abell, cofounder of ePC Group, a consulting firm. “It’s going to impact the whole organization.”

Reduced Out-of-Stocks and Improved Shelf Management. One of the greatest opportunities in the retail business is to increase top-line revenue growth is the increased availability of the right merchandise for the consumer. With RFID, replenishment is made more effective, mis-ships are identified immediately, and changes in product velocity are recognized in real time. Some studies have suggested a benefit of 3 to 5 percent increased sales resulting from implementation of RFID.

Improved Productivity and Streamlined Process. A.T.Kearney, a management consulting firm owned by EDS, says retailers will see benefits from a reduction of store and warehouse labor expenses of 7.5 percent. Another retail analyst, Sanford C. Bernstein, estimates that Wal-Mart alone could save $8.35 billion annually by using RFID, mostly in labor costs from not having to manually scan the bar codes of incoming goods. An Accenture study estimated efficiency gains related to labor costs ranging from 5 to 40 percent depending on existing levels of automation within the retail organization.

Reduced Shrinkage. Most likely, anyone reading this magazine already has a great appreciation for the levels of loss that occur each year for retailers. Studies of retail shortage around the world consistently show loss rates in the range 1.73% to 1.80% representing billions of dollars in loss. RFID has the potential to mitigate and reduce losses from multiple sources:

- Process Failures—Pricing errors, scanning errors, incorrect invoicing, processing of damages and returns, and direct-to-store deliveries.

- Internal Theft—Merchandise concealment, pass-through or sweetheart deals, fraudulent returns, vendor theft, and product diversion.

- External Theft—Shoplifting, returns fraud, and even burglary can be impacted by RFID.

We cannot underestimate the importance of the improved level of data available to us in our efforts to control shortage as a result of RFID. One of our problems in the loss prevention industry has always been the lack of data, what one researcher called a “data desert,” relative to shortage and loss prevention activities.

Improved Customer Satisfaction. Retailers are looking to RFID not only to reduce cost and improve inventory management, but they also recognize the potential for RFID-enabled technology to improve the customer experience, offering greater value, new and custom services, and seamless transactions, such as automated self checkout.

What Are the Obstacles for Wider Adoption of RFID?

While there are clearly exciting possibilities for RFID, hurdles remain. The obstacles below are the most often cited by industry experts and retail executives as needing to be addressed.

Costs. One of the key reasons RFID is gaining traction is the continued dropin tag costs over the years. But accurate data on tag costs is hard to come by, partly due to the continued decrease in price and the varying types of tags employed. A 2003 study by ARC Advisory Group found the average costs were 91 cents for a passive HF tag and 57 cents for a passive UHF tag. They expected unit prices to drop to an average of 16 cents per passive UHF tag by 2008 with high volume users possibly reaching the 5-cent mark. Others estimate that current pricing for UHF tags has already dropped into the 20-cent range.

With thousands of locations, millions of products, and high inventory turn rates, the retail marketplace is the primary future for RFID benefits.

The cost factor is also relative to the value of the item being protected or tracked. The goal of a 5-cent tag is clearly driven by the desire to tag vast quantities of relatively small value items at the item level. However, if you are jeweler with an average price point that runs into the hundreds of dollars or, as mentioned previously, a manufacturer of high-priced musical instruments, a 50-cent RFID tag could be well worth the cost.

Reliability. There are three primary issues with RFID technology—materials, wireless reliability, and electromagnetic interference. The first issue has to do with the material makeup of the items to be tagged. Since water absorbs radiowaves and metal reflects them, they both cause problems when present insignificant quantities.

We have all experienced the second issue, wireless reliability, in a different context—cell phones. Dropped cellphone calls or garbled communications due to moving too far away from cell tower coverage is still quite common.

Finally, the issue of electromagnetic interference deals with competing wireless signals that abound in our homes and workplaces. Wireless computer networks, wireless phones, microwave ovens, neon lights, security alarms, and the like all compete for bandwidth within assigned frequencies.

However, reliability and read rates might be better than some perceive. A recent study by systems integrator R4Global Services shows read rates in the 95 to 98 percent range. “There is a common perception among potential customers and even analysts that RFID systems can only deliver 80 percent read rates, and that is outdated and wrong,” says Jeff Richards, CEO of R4. Richards attributes the better performance to higher quality control standards at tag manufacturers.

Privacy. The leading opponent of RFID tagging due to privacy concerns is CASPIAN, Consumers Against Supermarket Privacy Invasion and Numbering, an activist group founded by Katherine Albrecht to voice privacy concerns related to frequent-shopper cards in the grocery business.

“[Our fear is] a global network of millions of receivers along the entire supply chain—in airports, seaports, highways, distribution centers, warehouses, retail stores—and in our home,” says Albrecht. “Imagine if these chips are in clothes and tires and shoes. Companies could know where you are at any time, anywhere in the world.”

There are others who have joined in expressing their concern for how RFID will affect privacy, including Byron Dorgan, the Democratic senator from North Dakota. However, he believes that the government could play a strong role in allaying those privacy concerns. Speaking at the Frontline Solutions Conference and Exposition in September of this year, he said, “We can observe this or be an active partner, playing a role in addressing the challenges [of RFID].”

One solution to these concerns that seems acceptable to the privacy groups is to keep RFID tags at the pallet and case level. This level of tracking addresses concerns about items being tracked to the individual level but, long term, limits the benefits of RFID technology to the retailer.

Another effort that received at least some encouragement from privacy groups was Marks & Spencer’s approach to their item-level test. During this test, Marks & Spencer made clear statements of what information would be tracked and ensured the public that no consumer-level information would be tracked and that the passive tags would only be activated by their own scanners. This approach prompted Katharine Albrecht of CASPIAN to comment, “We stand firm in our opposition to item level RFID tagging. But we do want to recognize Marks & Spencer’s responsible attitude toward the trial.”

What strategy should retailers use if they do want to gain the benefits of item-level RFID? At a workshop on customer perceptions of RFID, MilanTurk, Jr., director of global customer ebusiness at Proctor & Gamble, urged retailers to communicate and educate consumers about the benefits of RFID.

David Hogan, senior vice president and CIO of the National Retail Federation, compares the emergence of RFID to the adoption of bar codes in previous years. “Consumers learned that [bar] codes provide more price integrity and accuracy, support faster through put due to code scanning, and provide more detailed receipts of what was purchased,” says Hogan.

In fact, extending the comparison to bar codes, a Price waterhouse Coopers study from a few years ago estimated that bar codes save customers, retailers, and manufacturers $30 billion a year in the supermarket and mass-merchandise retail sectors.

Another strategy is for retailers to voluntarily adopt standards related to privacy and their deployment of RFID technology. Most experts agree the starting point on policy is to notify consumers that certain items are tagged, perhaps with some type of RFID logo on product packages. Following the Marks & Spencer example, the next step is to identify what information will be collected, how it will be used, and whether it will be shared—one of the primary privacy concerns of consumers. Finally, some privacy advocates suggest giving consumers the ability to “kill” the RFID tags as they leave the store.

Retailers see the opportunity from RFID to reduce costs, improve sales, and increase customer satisfaction primarily through streamlined inventory controls.

The popular press is starting to carry articles pointing out that while the privacy concerns over RFID are well intended, they are over blown. At least in today’s technology environment, the idea of “big brother” tracking your every movement is unrealistic. The fact is that the tags being deployed in the retail environment have such small antennas and, thus, create such a small signature that, as one columnist puts it, “to stalk someone wearing an RFID chip, you would have to be almost close enough to touch them.”

Infrastructure Requirements. The sheer volume of data that could potentially accrue from the implementation of RFID requires a sound plan that assesses the supporting technology infrastructure necessary to support it. One study estimates that if Wal-Mart were to implement item-level tracking, they would generate seven terabytes of RFID data each day.

“Companies are going to have problems when they drop RFID on top of shaky infrastructures,” says Kara Romanow, an analyst at AMR Research in Boston. Her concerns are echoed by Rainer Kerth, RFID architect at IBM, who observes, “There’s a lot of excitement around RFID, and rightfully so, but when you take a step back and consider the consequences, data management if one of the bigger issues.” IT executives and senior leadership teams are already recognizing the challenge. John Keith, senior vice president of IT applications at Unilever, observed as much during a recent roundtable on RFID. “Our concerns are more about the data, There’s so much data. What are we going to do with all of it? How are we going to modify our existing systems to accommodate all the data coming our way?” asks Keith.

Conclusions for LP Professionals

The short-term forecast for RFID in the retail setting is clearly focused on the pallet and case pack level and will produce the greatest benefits at the supply-chain level. Item-level tagging will be coming in the next four to six years as organizations address the identified challenges to prepare for an enterprise solution with all the attendant benefits.

As a loss prevention practitioner, here’s what you can do to prepare yourself and assist your organization:

- Stay up-to-date on what others are doing, RFID tests, technology improvements, privacy concerns, and news. Some excellent resources for this information include RFID Journal (www.rfidjournal.com), Accenture (www.accenture.com), CapGemini (www.capgemini.com), and Managing Automation (www.managingautomation.com.)

- Get involved with your organization’s efforts and volunteer to help on task forces, committees, or project teams addressing this issue.

- Begin a dialogue with your current EAS providers and within your organization to discuss the migration path to RFID from your current EAS technology.