Since the September 11 terrorist attacks, a tremendous amount of attention and resources have been focused on preventing the smuggling of weapons onto aircraft and the entry of possible terrorists into the country. But what’s being done to prevent introduction of biological, nuclear, or other weapons of mass destruction through the millions of containers of products and goods imported into the country by manufacturers and retailers?

Each year, an estimated 16 million cargo containers measuring up to forty feet long enter the country. U.S. Customs inspects only about three percent of those containers. If you were a terrorist organization looking for a relatively safe method of smuggling contraband into the U.S., what better way than to bribe or steal your way into poorly secured distribution facilities in Indonesia, Pakistan, or China where goods are prepared or held for transportation to the U.S.

Last year, Italian authorities arrested Amir Farid Rizk inside a shipping container bound for Canada. While he has denied any connections with terrorist organizations, Rizk was found with a satellite phone, a laptop computer, and security passes for airports in Canada, Thailand, and Egypt.

Because of this potential threat and the daunting task before the U.S. Customs Service, a joint government-business initiative was unveiled in April of this year to address the problem. Called Customs-Trade Partnership Against Terrorism, or C-TPAT, the program involves retailers and other importers meeting recommended security requirements throughout their entire supply chain in return for priority treatment when their goods enter the country.

“We can’t examine every shipment, and we don’t want to,” says Customs Service Commissioner Robert C. Bonner, one of the architects of the plan. “If a business takes steps to secure its cargo against terrorism, we will give it the ‘fast lane’ through the border.

“This program improves the security of our border and our nation, and at the same time it speeds the processing at the borders for companies to have much more predictable delivery schedules for their products.”

Secretary of Treasury Paul O’Neill concurs with Bonner. “Our nation’s economy relies heavily on the ability to move cargo across our borders quickly—in full compliance with the law,” says O’Neill. “As a former CEO myself, I know it is critical to engage American businesses in our fight against terrorism. C-TPAT does just that.”

How C-TPAT Works

Businesses must apply to participate in C-TPAT. Membership is available to importers, carriers, brokers, warehouse operators, and manufacturers.

Participants sign an agreement that commits them to the following actions:

- Conduct a comprehensive self-assessment of their supply-chain security procedures using guidelines jointly developed by U.S. Customs and the trade community.

- Submit a supply-chain security questionnaire to Customs.

- Develop and implement a program that enhances security throughout the supply chain.

- Communicate C-TPAT guidelines to other companies in the supply chain and work toward building the guidelines into relationships with those companies.

The first step in the process requires a company to review the security procedures throughout the supply chain from the point of origin through each step of transporting the goods to this country. This involves not just understanding what your company’s procedures are when the goods are in your direct control, but also those procedures employed by your manufacturing and transportation partners throughout the world.

Conducting an assessment of this scope at first appears monumental to many companies. However, according to Barry Wilkins, worldwide director of transportation and supply-chain security for Pinkerton Consulting & Investigations and a consultant to many companies implementing C-TPAT recommendations, the process is not as cumbersome as initially thought.

“The reality is that most of the suppliers that you are going to ask questions of have more than likely already been asked and are already working on improving their procedures because they want the business,” says Wilkins.

The self-assessment compares a company’s current policies and procedures against those recommended by the C-TPAT taskforce. There are different sets of guidelines to apply to specific segments of the import chain, such as a carrier, broker, importer, or warehouse.

The guidelines focus on the following areas:

procedural security, physical security, personnel security, education and training, access controls, manifest procedures, and conveyance security see (saibar page(20)

when a company signs up to participate in the CTPAT program, they agree to conduct their self-assessment within sixty to ninety days. At the end of that period, a formal document is given to U.S. Customs reporting the results of the self-assessment.

Depending on the company, developing and implementing the recommendations should not be an overwhelming task.

“Customs is not looking for perfection,” explains Wilkins. “They’re looking for a commitment to improve. They know there are deficiencies in the supply chain. What they’re hoping to do is get people to sign up to work toward improving those deficiencies. They want you to assess it, identify problems, and work toward fixing the problems.”

Where Loss Prevention Fits In

Since most of the requirements of C-TPAT focus on security issues, retail loss prevention organizations are deeply involved when their companies join the C-TPAT initiative.

Kelby Woodard, director of supply chain assets protection for Target Corporation, has been involved with C-TPAT since the first discussions of the concept began in October 2001. Target was one of the original seven companies who initiated the program, along with BP America, Daimler Chrysler, Ford Motor Company, General Motors, Motorola, and Sara Lee.

Because his organization is responsible for theft investigations and security of Target’s transportation and warehouses both domestically and internationally, “From a security process standpoint, C-TPAT falls squarely on assets protection shoulders,” says Woodard.

Woodard’s team has partnered internally with Target’s customs broker department, which is responsible for import administration. The team is responsible for all Target Corporation operating units, including Mervyn’s, Marshall Fields, and Target stores.

For the most part, the C-TPAT requirements involve documenting those practices already in place. “I think most people would be surprised, when they start going through.”

Securing the Global Supply Chain

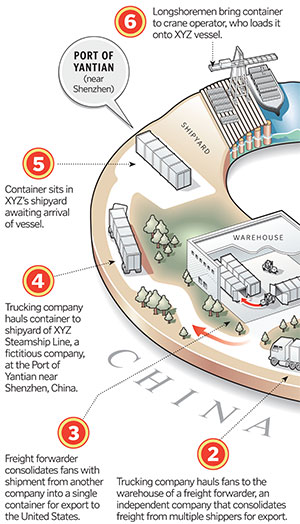

When products move from point of manufacture to the United States, they pass through multiple vendors, facilities, and legal jurisdictions. Throughout the journey, there are multiple points of vulnerability for either theft or introduction of contraband by organized crime or terrorist organizations. The illustration above shows the journey of a fictional shipment of ceiling fans from a factory in China to an importer in the U.S. Although there are security concerns along the entire route, each of the steps shown represents a potential point of vulnerability. (Illustration reprinted with permission from the Charlotte Observer.)

their supply chains in depth, how many practices they already have in place to secure the supply chain,” says Woodard. “We certainly understand our supply chain from an assets protection perspective much better as a result of the reviews we’ve done, which is a key benefit.”

That understanding has translated into tighter procedures as well as greater awareness throughout the organization.

“We have spent a tremendous amount of time overseas training not only Target employees, but also our vendors,” says Woodard.

While there are no dedicated assets protection personnel overseas, Woodard’s training has essentially “deputized” their overseas associates and outside consultants so they better understand the issues and what’s important from an assets protection point of view.

Not only has the C-TPAT process helped lower the risk that terrorism can enter into the supply chain, as a secondary benefit it also addresses those on-going loss prevention issues of cargo theft and drugs entering the supply chain.

“It makes good business sense,” concludes Woodard.

Wilkins agrees. “If having goods in their factories and on their store shelves is important, retailers need to get on board.”

For more information on C-TPAT, go to the U.S. Customs web site,